Assembling And Wiring Cables 620 Ipc Standards

€200,00 – €305,00

This is the latest revision of the only industry-consensus standard for Requirements and Acceptance of Cable and Wire Harness Assemblies IPC/WHMA-A-620C, and it includes new sections for safety wiring, safety cable, grommets, and raceways along with updated information across many of the sections

Detailing setting, goal and main character. Honoo no haramase oppai episode 2 1080p.

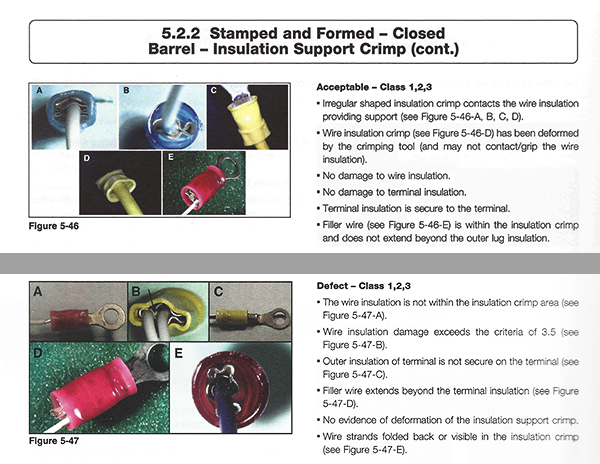

Greenstock In-connect is proud to be one of the few UK manufacturers to produce cable and wire harness products to the IPC/ WHMA-A-620 Standard (now, Revision C). This is the only industry-consensus standard for Requirements and Acceptance for Cable and Wire Harness Assemblies and the most widely used inspection specification for the cable and wire harness assembly industry. This standard does not provide criteria for cross-section or X-ray evaluation. Purpose This standard describes materials, methods, tests and acceptability criteria for producing crimped, mechanically secured, or soldered interconnections and the related assembly activities associated with cable and harness assemblies.

Description

This is the latest revision of the only industry-consensus standard for Requirements and Acceptance of Cable and Wire Harness Assemblies IPC/WHMA-A-620C, and it includes new sections for safety wiring, safety cable, grommets, and raceways along with updated information across many of the sections. With over 700 photographs and illustrations, this standard describes materials, methods, tests and acceptance criteria for producing crimped, mechanically secured and soldered interconnections and the related assembly activities associated with cable and harness assemblies.

IPC/WHMA-A-620C was developed by IPC and the Wire Harness Manufacturers Association (WHMA).

Additional information

| Date of Publication: | January 30, 2017 |

|---|---|

| Language | English, French, German, Spanish |

| Number of Pages: | 422 |

| Product options | Hardcopy, PDF: Single User Download (Non-Printable) |

Related products

J-STD-033C-1: Handling, Packing, Shipping and Use of Moisture/Reflow Sensitive Surface Mount Devices

€69,00 – €79,00IPC-7093: Design and Assembly Process Implementation for Bottom Termination Components

€168,00 – €234,00

| Kitting | Trays |

|---|---|

|

|

| Racks | Cables and Harnesses |

|---|---|

|

|

| Wire Marking | CAD Design |

|---|---|

|

|

Technical Specifications

Ipc 620 Meaning

| Manufacturing Capabilities |

|

|---|---|

| Harness Features |

|

| Connector Types |

|

| Covering |

|

| Insulation Type |

|

| Wire and Cable Length |

|

| Wire and Cable Thickness |

|

| Testing and Inspection |

|

| Production Volume |

|

| Turnaround Times |

|

| Value Added Services |

|

| Industry Focus |

|

| Intended Application |

|

| Industry Standards |

|

| File Formats |

|